APPLICATIONS:

Raman Spectrometer

Raman Spectrometer

Manufacturing and Packaging of Semiconductors

Home » Applications » Raman Spectrometer » Manufacturing and Packaging of Semiconductors

The capacity of the Raman microspectroscopy has been well exploited in the field of semiconducting materials. It can detect with no sample preparation microinhomogeneities in integrated circuits, defects in both optoelectronic, microelectronic and sensor devices, that are of special technological interest in connection with their possible influence on the device performance. The method also permits quantitative and nondestructive microanalysis of structures and electrical properties in semiconductors. These mainly include damage induced by ion implantation, strains in heterostructures, measurements of crystallographic orientations, polycrystalline grains size and free carriers concentration.

Applications:

Material purity

Defect analysis

Alloy composition

Superlattice structure

Pollutant identification

Semiconductor heterostructure

Doping effect of heterojunction

Characteristic factors of intrinsic stress & strain

Photoluminescence microscopic analysis of material purity

Example: Photoresist (residue) detection

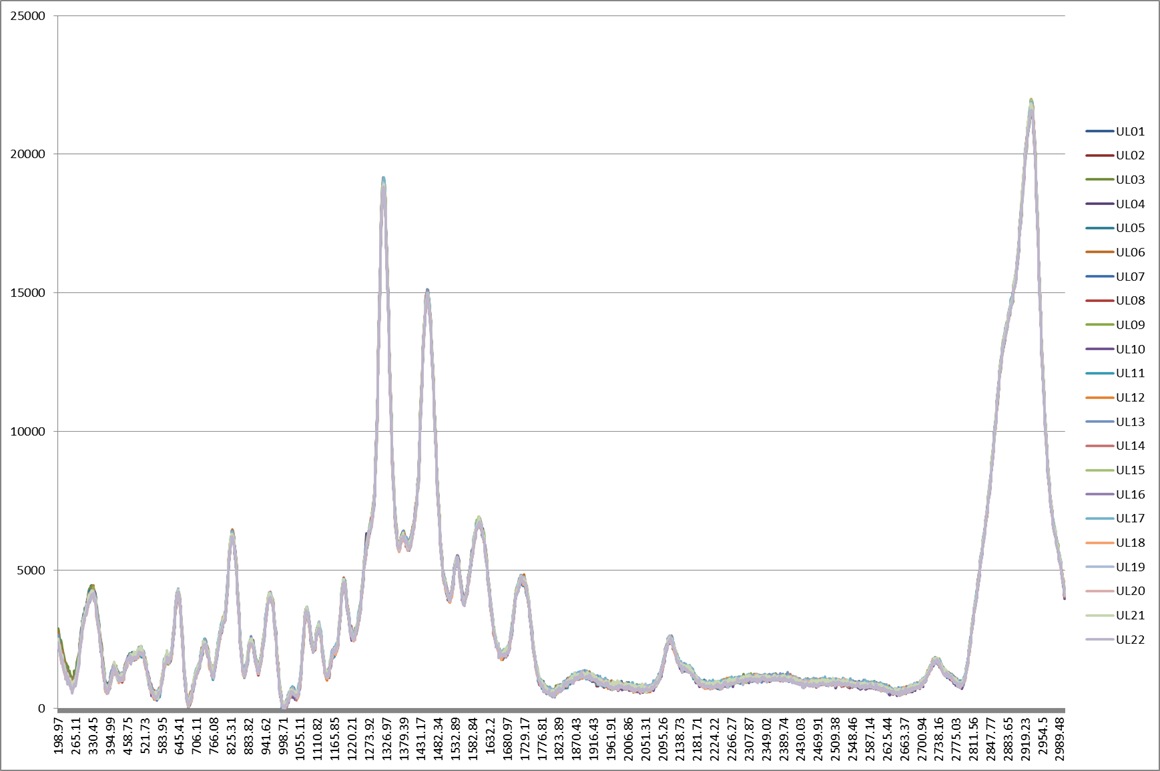

For sample group A: PR_UL photoresist with the same composition and concentration. The test is performed, and the highly consistent results can be obtained by observing the Raman spectrum.

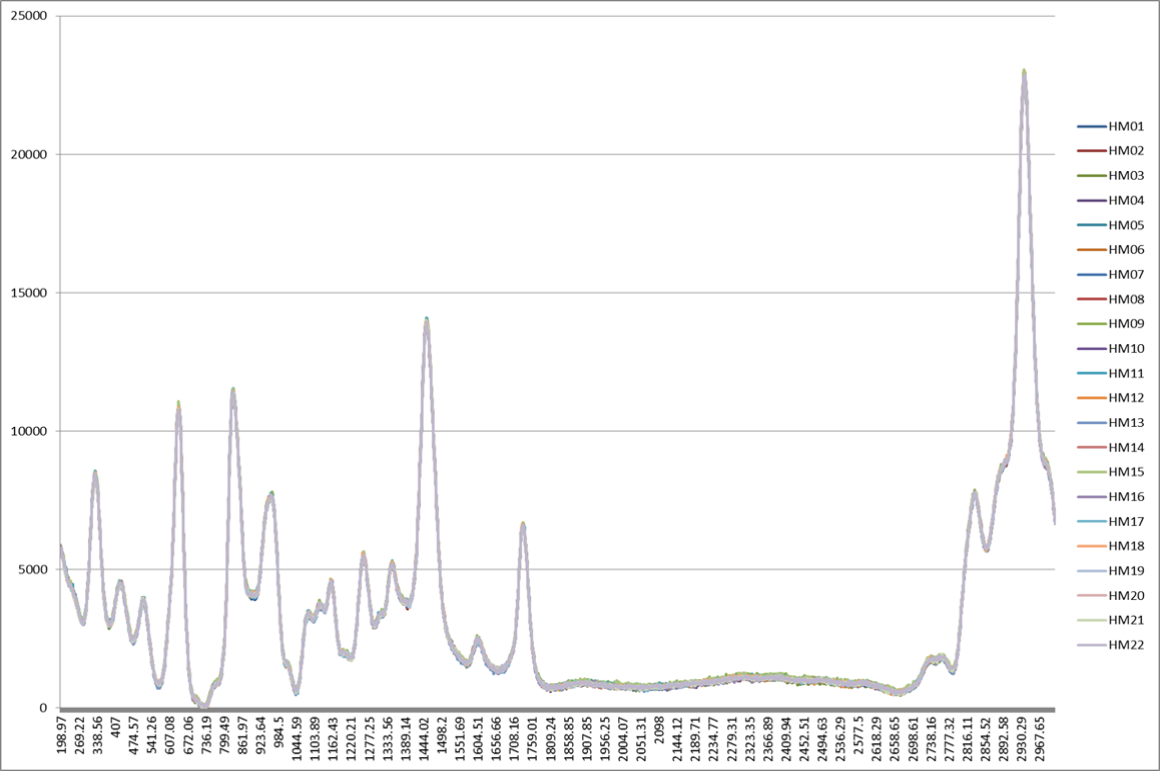

For sample group B: PR_HM photoresist with the same composition and concentration. The test is performed, and the highly consistent results can be obtained by observing the Raman spectrum.

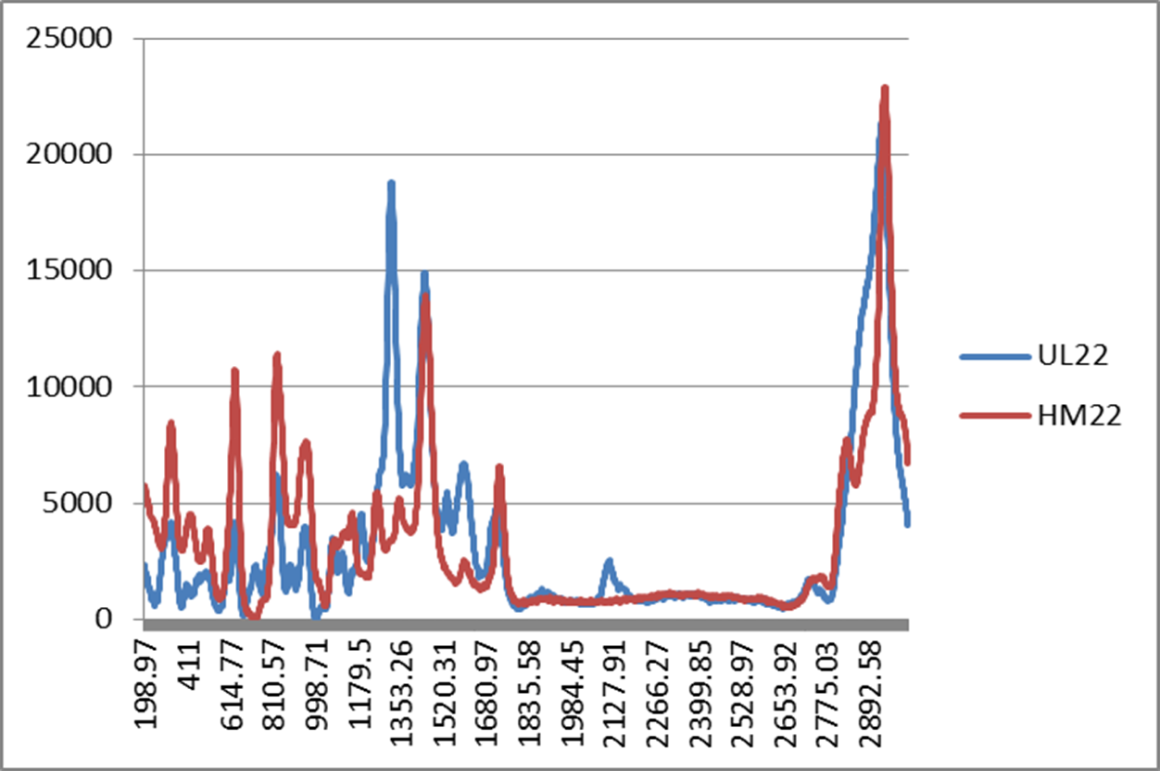

Sample group A & B, judging and distinguishing two photoresists with different components.

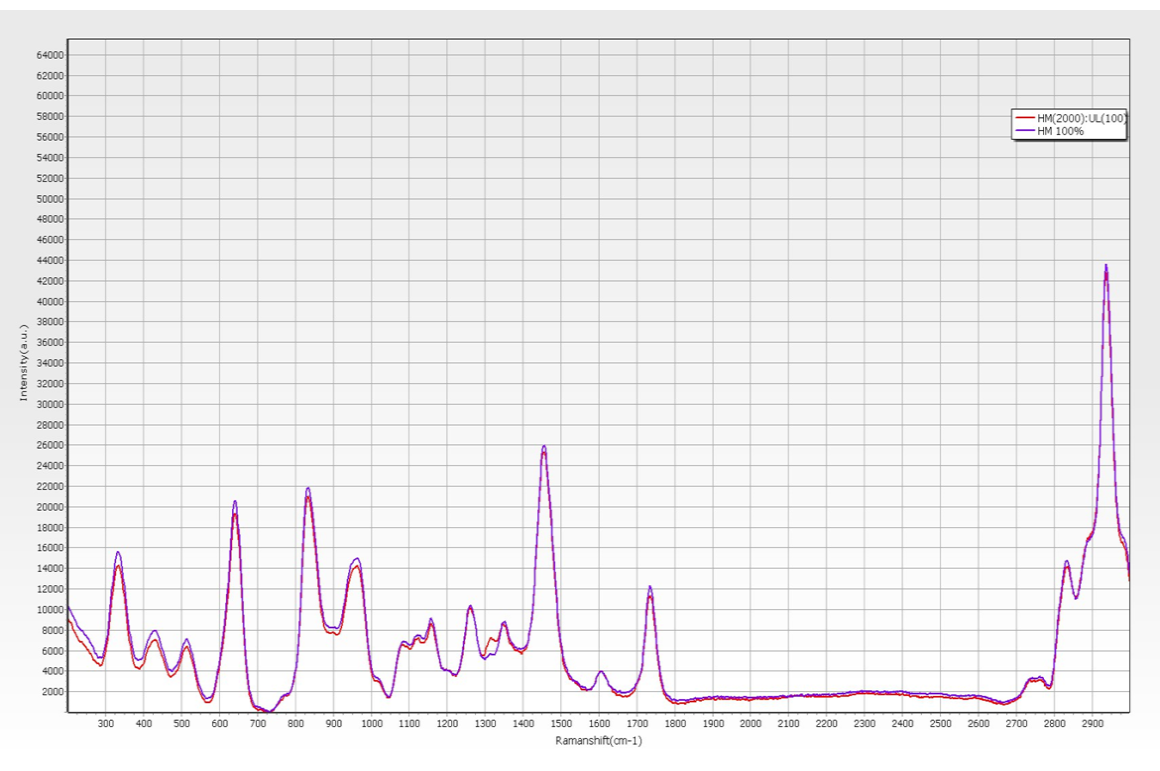

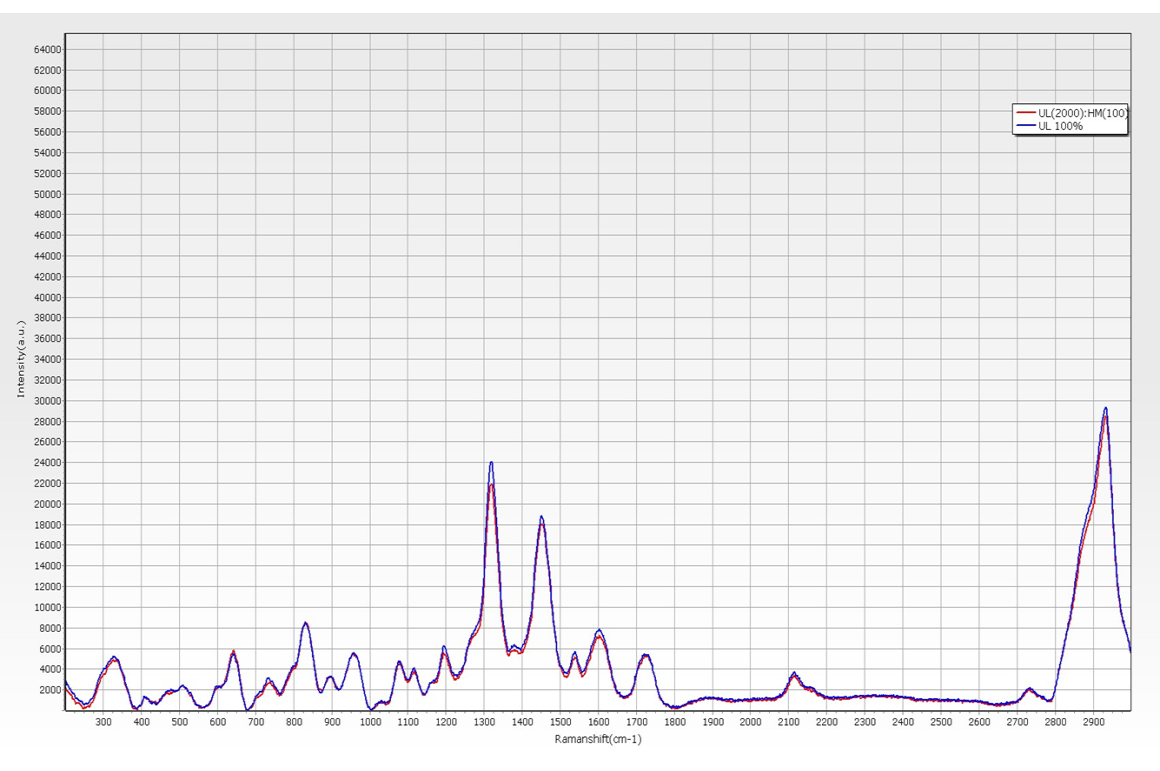

With the Raman analyzer, you can easily see if there is any contamination in the photoresist: UL+5% HM vs. 100% UL.

With the Raman analyzer, you can easily see if there is any contamination in the photoresist: HM+5% UL vs. 100% HM.